Crash Test Dummies’ Worst Nightmare: How Safety Engineering is Revolutionizing Autos

1. The Evolving Landscape of Automotive Safety:

The automotive industry faces unprecedented challenges in safety engineering. While advancements like Electronic Stability Control (ESC) and Anti-lock Braking Systems (ABS) have significantly reduced fatalities, the rise of autonomous vehicles (AVs) and increasing vehicle complexity demand a paradigm shift in safety design and validation. Traditional crash testing methodologies, while crucial, are becoming increasingly insufficient to comprehensively assess the risks associated with advanced driver-assistance systems (ADAS) and complex interactions between vehicle systems. Furthermore, the increasing prevalence of lightweight materials, while improving fuel efficiency, presents new challenges in occupant protection, demanding sophisticated finite element analysis (FEA) and advanced material modeling techniques.

2. Beyond the Crash Test: A Multifaceted Approach:

Modern safety engineering necessitates a holistic approach transcending the limitations of physical crash testing. This includes a robust integration of:

- Proactive Safety Design: Emphasis on preventing accidents through features like advanced driver-monitoring systems (DMS), pedestrian detection, and automated emergency braking (AEB) systems with improved sensor fusion algorithms. Quantitative risk assessment methodologies, such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA), are crucial in identifying and mitigating potential hazards early in the design process.

- Predictive Safety Simulation: High-fidelity simulations using computational fluid dynamics (CFD) and multi-body dynamics (MBD) are indispensable for analyzing complex crash scenarios, optimizing vehicle structures, and validating ADAS performance under diverse conditions. These simulations leverage advanced algorithms, including machine learning, to predict and mitigate risks more accurately than traditional methods.

- Data-Driven Safety Enhancement: The increasing availability of real-world driving data offers unprecedented opportunities for improving safety. Analysis of this data, utilizing statistical methods and machine learning techniques, allows for the identification of high-risk scenarios and refinement of safety systems based on actual driving behaviour.

3. The Stakes are High: A Call to Action:

The imperative for enhanced automotive safety is not merely a matter of regulatory compliance; it is a fundamental ethical and economic necessity. Reducing road accidents saves lives, minimizes healthcare costs, and strengthens brand reputation. This blog post explores the cutting-edge technologies and methodologies driving the revolution in automotive safety, highlighting the challenges and opportunities that lie ahead for engineers and business leaders alike. The future of automotive safety hinges on a commitment to innovation, collaboration, and a relentless pursuit of safer roads.

Analysis of the Safety Engineering Market: Key Trends and Actionable Insights

The safety engineering market is undergoing significant transformation driven by technological advancements, evolving regulatory landscapes, and a heightened focus on corporate social responsibility. This analysis identifies key trends, categorizes them, and provides actionable insights for market strategists.

I. Positive Trends:

A. Increased Adoption of Digital Technologies:

- Trend: The integration of IoT, AI, machine learning, and digital twins is revolutionizing safety management. Predictive maintenance, real-time risk assessment, and improved incident investigation are becoming commonplace.

- Underlying Factor: The declining cost and increasing sophistication of these technologies, coupled with a growing understanding of their ROI in safety improvement, fuel their adoption.

- Impact: Businesses leveraging these technologies gain a competitive advantage through enhanced safety performance, reduced downtime, and improved operational efficiency.

- Example: Companies like Rockwell Automation are incorporating AI-powered predictive analytics into their industrial automation systems to detect anomalies and prevent potential hazards before incidents occur.

- Actionable Insight: Invest in R&D and strategic partnerships to integrate digital technologies into existing safety management systems. Develop robust data analytics capabilities to extract actionable insights from the generated data.

B. Growing Emphasis on Human Factors Engineering:

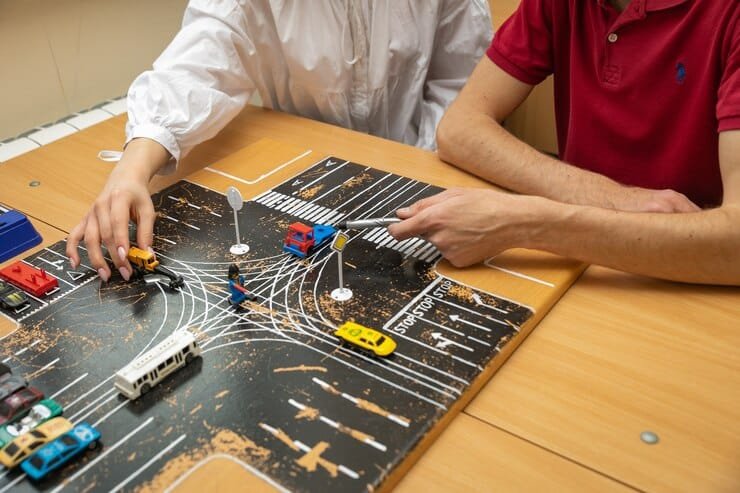

- Trend: A shift from purely technical solutions towards a more holistic approach that considers human error and behavioral aspects as primary contributors to accidents.

- Underlying Factor: Recognition that human error is a significant factor in most incidents, leading to a greater emphasis on designing systems and processes that account for human limitations and cognitive biases.

- Impact: Companies focusing on human factors engineering enhance safety culture, improve worker training, and reduce human error-related incidents.

- Example: Boeing’s post-737 MAX crisis efforts have included a significant focus on improving pilot training and human-machine interface design.

- Actionable Insight: Integrate human factors principles throughout the entire lifecycle of safety-critical systems. Invest in training programs focused on human error reduction and develop comprehensive Human Reliability Analysis (HRA) methodologies.

II. Adverse Trends:

A. Cybersecurity Threats in Industrial Control Systems (ICS):

- Trend: Increased connectivity in industrial environments increases vulnerability to cyberattacks, potentially leading to safety breaches and catastrophic failures.

- Underlying Factor: The convergence of IT and OT networks creates a larger attack surface, and legacy systems often lack sufficient cybersecurity measures.

- Impact: Companies face significant financial and reputational risks associated with cyberattacks targeting safety-critical systems.

- Example: The Stuxnet virus demonstrated the potential for malicious cyberattacks to compromise industrial control systems and cause physical damage.

- Actionable Insight: Implement robust cybersecurity protocols for ICS, including network segmentation, intrusion detection/prevention systems, and regular vulnerability assessments. Employ security-by-design principles in new system development.

B. Skills Gap in Safety Engineering:

- Trend: A shortage of qualified safety engineers with expertise in emerging technologies like AI and cybersecurity.

- Underlying Factor: Rapid technological advancements outpace the development of relevant educational programs and training opportunities.

- Impact: Companies struggle to find and retain skilled professionals, hindering their ability to effectively implement advanced safety solutions.

- Actionable Insight: Invest in employee training and development programs to upskill existing staff. Collaborate with universities and training institutions to develop tailored curriculum aligned with industry needs. Attract and retain talent through competitive compensation and benefits packages.

Conclusion:

The safety engineering market presents both exciting opportunities and significant challenges. By proactively addressing the identified trends and implementing the suggested actionable insights, companies can enhance their competitive position, mitigate risks, and drive continuous improvement in safety performance. A holistic approach combining technological advancements with a strong focus on human factors is crucial for success in this evolving landscape.

Automotive Engineering: Advanced Driver-Assistance Systems (ADAS)

The development and implementation of ADAS features, such as Automatic Emergency Braking (AEB) and Lane Keeping Assist (LKA), heavily rely on safety engineering principles. Fault Tree Analysis (FTA) is used to identify potential system failures leading to accidents. For example, an FTA might reveal that a sensor malfunction combined with software error could cause AEB to fail. Failure Modes and Effects Analysis (FMEA) is then employed to assess the severity, probability, and detectability of each failure mode, prioritizing mitigation efforts. This rigorous process ensures a high level of functional safety, meeting stringent ISO 26262 standards. Quantitative risk assessment using techniques such as Markov chains might model the probability of different accident scenarios given various system failures, informing design decisions and setting safety goals (ASIL levels).

Manufacturing: Robotics and Automation

In automated manufacturing plants, safety engineering is crucial for worker protection. Risk assessments considering hazards like pinch points, crushing forces, and high-speed movements are paramount. Safety instrumented systems (SIS), employing PLCs and safety relays, are implemented to rapidly shut down equipment in hazardous situations, meeting performance level (PL) requirements defined by IEC 61508. Laser scanners and light curtains create safety zones around robots, stopping operation if a worker enters. Regular audits and Functional Safety Assessments (FSA) ensure ongoing compliance with standards and identify areas for improvement. Quantitative risk assessment using HAZOP (Hazard and Operability Study) methodologies help evaluate the effectiveness of safety measures.

Healthcare: Medical Device Safety

The design and manufacture of medical devices require stringent safety engineering practices. A critical aspect is the application of IEC 62304, defining software lifecycle processes for medical device software. For example, in designing an infusion pump, a Hazard Analysis and Risk Control (HARC) process identifies potential hazards like over-infusion. Then, safety requirements are derived, specifying functionalities like drug-library checks and independent flow verification to mitigate risks. Software verification and validation, including unit testing, integration testing, and system testing, ensure the software meets its safety requirements, aiming for a high level of software assurance and reducing the risk of failure to an acceptable level.

Technology: Cybersecurity and Data Integrity

While seemingly less tangible, cybersecurity is a critical aspect of safety engineering in software development. Secure coding practices are vital to preventing data breaches and system failures. Threat modeling identifies potential vulnerabilities and helps in implementing security controls. For example, a secure software development lifecycle (SDLC) incorporating techniques like penetration testing and code reviews, is essential for high-reliability applications like autonomous driving systems. Quantitative risk assessments determine the acceptable risk level and guide resource allocation for security measures, minimizing the probability of cyberattacks impacting system functionality or safety.

Leveraging AI and Machine Learning for Predictive Maintenance

Several safety engineering companies are integrating AI and ML into their offerings since 2023. This allows for predictive maintenance of safety-critical systems in automotive applications. For example, a company might analyze sensor data from a vehicle’s braking system to predict potential failures before they occur, enabling proactive repairs and reducing the risk of accidents. This move towards predictive capabilities is a key organic growth strategy.

Strategic Partnerships and Acquisitions (Inorganic Growth)

Companies are forming strategic alliances and making acquisitions to expand their product portfolios and market reach. A prominent example could be a safety systems provider acquiring a smaller company specializing in cybersecurity for connected vehicles. This acquisition immediately expands their offerings, addressing the growing need for secure and reliable safety systems in autonomous driving technologies. This synergistic approach boosts the company’s capability and market share rapidly.

Expanding into New Geographies and Markets

To capture a larger share of the global automotive safety market, companies are actively expanding into new regions with strong automotive industries. For example, a company might establish a new research and development center in a country with a booming electric vehicle sector, allowing them to better serve the local market needs and tailor solutions specifically for that region’s regulations and infrastructure. This geographical expansion constitutes an organic strategy.

Developing Integrated Safety Platforms

Instead of offering individual safety components, companies are now building integrated safety platforms. This involves creating holistic solutions that combine various safety technologies, such as advanced driver-assistance systems (ADAS), collision avoidance systems, and occupant protection systems. This integrated approach simplifies integration for automotive manufacturers and offers a comprehensive safety solution, increasing their value proposition and acting as an organic growth strategy.

Enhanced Cybersecurity Measures

Given the increasing reliance on connected vehicles and software-defined systems, cybersecurity is paramount. Safety engineering companies are proactively developing and integrating enhanced cybersecurity measures into their products since 2023. This includes implementing robust authentication protocols, intrusion detection systems, and regular software updates to protect against cyber threats and maintain the integrity of safety-critical systems. This enhances the product value proposition (organic growth).

Subscription-Based Service Models

Many companies are shifting towards subscription-based models for software and data services related to safety engineering. This allows for ongoing monitoring, updates, and analysis, which keeps customers up-to-date with the latest safety technology and provides valuable insights into system performance. This recurring revenue stream fosters sustained growth (organic).

Outlook & Summary: The Trajectory of Automotive Safety

The automotive industry is at a pivotal juncture, transitioning from incremental safety improvements to a paradigm shift driven by advancements in safety engineering. The next 5-10 years will witness an exponential growth in the application of AI, machine learning (ML), and sophisticated sensor fusion technologies. Expect to see a dramatic increase in the deployment of Advanced Driver-Assistance Systems (ADAS) moving beyond Level 2 automation towards higher levels of autonomy, incorporating features like predictive collision avoidance, proactive pedestrian protection, and highly integrated occupant safety systems.

Key Technological Advancements:

- High-Fidelity Simulation & Virtual Prototyping: Finite Element Analysis (FEA) and computational fluid dynamics (CFD) will become even more sophisticated, enabling the prediction of crashworthiness and injury biomechanics with unprecedented accuracy, reducing reliance on physical crash testing. This will lead to faster development cycles and reduced R&D costs.

- Sensor Integration & Data Analytics: The proliferation of LiDAR, radar, cameras, and ultrasonic sensors will enable real-time environmental perception and risk assessment, significantly improving the effectiveness of ADAS and autonomous driving systems. Data analytics will play a crucial role in identifying and mitigating safety vulnerabilities.

- Biomechanics and Human Factors: A deeper understanding of human injury mechanisms will inform the development of more effective restraint systems, occupant compartment design, and injury mitigation strategies. This will incorporate personalized safety parameters based on anthropometric data.

Safety Engineering’s Role in Automotive Engineering:

Safety engineering is no longer a reactive discipline but a proactive force shaping the entire automotive engineering landscape. It is intrinsically linked to powertrain development (e.g., battery safety in EVs), vehicle dynamics control (e.g., ESC), and even manufacturing processes (e.g., ensuring consistent quality control). Its influence will only grow as the industry moves towards highly automated vehicles.

Key Takeaway: The future of automotive safety hinges on a holistic approach integrating advanced technologies with a deep understanding of human factors. The industry is transitioning towards a proactive, data-driven safety paradigm, where accidents are anticipated and prevented rather than simply mitigated.

A Critical Question: How can the automotive industry effectively address the ethical and legal challenges associated with increasingly autonomous vehicles and the complex interplay of responsibility in accident scenarios?