Electric Motors: The Silent Revolution Reshaping Automotive Manufacturing? – An Overview

The automotive industry is undergoing a seismic shift. The hum of the internal combustion engine, a defining sound of the 20th century, is fading, replaced by the near-silent whir of the electric motor. This quiet revolution isn’t just a change in sound; it’s a fundamental restructuring of manufacturing processes, supply chains, and even the skills needed to build vehicles. This blog post explores the core of this transformation: electric motors.

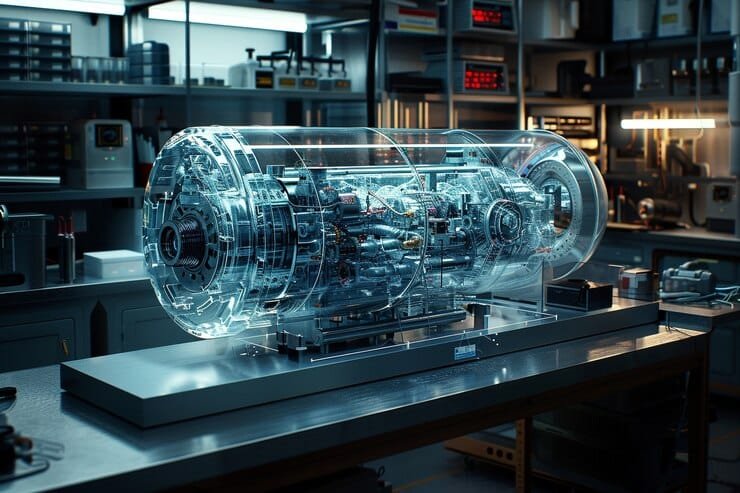

- The Current Landscape: Let’s start with the big picture. Electric vehicle (EV) sales are surging globally, driven by environmental concerns, government regulations, and the increasing affordability of EVs. This explosive growth creates unprecedented demand for efficient, reliable, and cost-effective electric motors. [Insert image here: Graph showing growth of EV sales over the last 5 years]. But the manufacturing of these motors presents unique challenges and opportunities.

- Why Electric Motors Matter: The electric motor is the heart of every EV. Its performance directly impacts the vehicle’s range, acceleration, efficiency, and ultimately, its market success. Understanding the nuances of electric motor design, manufacturing, and integration is paramount for automotive manufacturers aiming for a competitive edge. This requires a holistic approach, considering not just the motor itself, but also its power electronics, thermal management, and integration with the vehicle’s battery system.

- Navigating the Complexity: This blog will guide you through the key considerations involved in electric motor manufacturing. We’ll break down complex processes into easily digestible steps, exploring topics such as:

- Motor Selection: Choosing the right motor type for specific vehicle applications.

- Manufacturing Processes: A look at the different manufacturing techniques used, from winding and assembly to testing and quality control.

- Supply Chain Optimization: Strategies for managing the complexities of the electric motor supply chain.

- Future Trends: Exploring emerging technologies and innovations shaping the future of electric motor manufacturing.

This post isn’t just for engineers; it’s for all business leaders involved in the automotive sector. Whether you’re responsible for procurement, production, or R&D, understanding the intricacies of electric motors is crucial for navigating the exciting, yet challenging, future of automotive manufacturing. Let’s delve in.

Analyzing the Electric Motors Market: Trends and Actionable Insights

The electric motors market is undergoing a significant transformation, driven by technological advancements, evolving regulations, and shifting consumer preferences. Understanding these trends is crucial for strategic planning.

1. Positive Trends:

a) Increased Demand from Electrification: The burgeoning electric vehicle (EV) market is a primary driver of growth. This demand extends beyond cars to encompass electric buses, trucks, and even aircraft. Furthermore, the electrification of industrial processes and building automation is fueling demand for higher-efficiency motors.

- Impact: Companies specializing in high-power density, high-efficiency motors (e.g., permanent magnet synchronous motors) are experiencing significant growth.

- Actionable Insight: Invest in R&D for high-performance motors optimized for specific applications (e.g., traction motors for EVs, highly efficient motors for industrial pumps). Explore strategic partnerships with EV manufacturers and industrial automation companies. Example: Companies like Siemens and ABB are expanding their EV motor production and actively collaborating with automakers.

b) Advancements in Power Electronics: Improvements in power electronics, particularly in inverters and controllers, are enabling more efficient and precise control of electric motors. This leads to better energy efficiency, reduced operating costs, and enhanced performance.

- Impact: Companies capable of integrating advanced power electronics with their motors are gaining a competitive edge.

- Actionable Insight: Invest in integrating advanced power electronics into motor designs, focusing on miniaturization and improved efficiency. Develop sophisticated control algorithms for optimized motor performance. Example: Infineon Technologies is a leading provider of power semiconductors that are crucial for efficient electric motor control.

c) Growing Adoption of Smart Motors: The integration of sensors, communication protocols (like IoT), and data analytics is transforming electric motors into “smart” devices. This enables predictive maintenance, real-time performance monitoring, and improved energy management.

- Impact: Companies offering smart motor solutions with data analytics capabilities are creating new revenue streams through service offerings.

- Actionable Insight: Develop smart motor solutions with integrated sensors and connectivity. Invest in data analytics capabilities to extract insights from motor performance data and offer predictive maintenance services. Example: Several motor manufacturers are embedding digital twins of their motors to enhance predictive maintenance.

2. Adverse Trends:

a) Supply Chain Disruptions: The global supply chain continues to face challenges impacting the availability of raw materials (like rare-earth magnets) and components.

- Impact: Increased lead times, price volatility, and potential shortages of crucial components.

- Actionable Insight: Diversify sourcing strategies to reduce dependence on single suppliers. Invest in inventory management systems to mitigate supply chain risks. Explore alternative materials and designs to reduce reliance on scarce resources.

b) Increasing Regulatory Scrutiny: Environmental regulations are becoming stricter, pushing for higher energy efficiency and reduced emissions. This necessitates compliance with evolving standards.

- Impact: Increased compliance costs and potential penalties for non-compliance.

- Actionable Insight: Proactively invest in R&D for highly efficient motors meeting stringent environmental standards. Establish robust compliance programs to ensure adherence to regulations.

c) Intense Competition: The electric motor market is becoming increasingly competitive, with both established players and new entrants vying for market share.

- Impact: Pressure on pricing and profit margins.

- Actionable Insight: Focus on differentiation through innovation, superior quality, and specialized application solutions. Develop strong brand recognition and customer relationships.

By carefully addressing these positive and adverse trends, electric motor companies can position themselves for success in this dynamic and rapidly evolving market. A proactive and adaptable approach is critical for navigating the challenges and leveraging the opportunities that lie ahead.

1. Healthcare: Electric motors power hospital beds, allowing for easy adjustment of height and position, improving patient care and reducing strain on healthcare workers. This improves efficiency and patient comfort. Strategic consideration: Investing in quieter, more reliable motors increases patient satisfaction and reduces maintenance costs.

- Technology: Data centers rely heavily on electric motors for cooling systems. Large fans, driven by powerful motors, circulate air to dissipate heat generated by servers. Failure here can lead to costly downtime. Strategic consideration: Implementing predictive maintenance using motor vibration analysis can prevent costly failures and extend the lifespan of cooling systems.

- Automotives: Electric Vehicle (EV) manufacturing is entirely dependent on electric motors. These motors power the vehicle, providing torque and speed control. The efficiency and performance of these motors directly impact the vehicle’s range and performance. Strategic consideration: Focus on developing higher efficiency motors with improved power density to enhance EV range and reduce charging time. Investment in battery technology for optimal motor performance is also key.

- Manufacturing: Electric motors drive conveyors, robots, and other automated systems in factories. In automotive assembly lines, for example, precisely controlled motors ensure accurate placement of parts on the assembly line. Strategic consideration: Implementing energy-efficient motors reduces operational costs and minimizes the factory’s carbon footprint. Adopting advanced motor control systems enhances production efficiency and precision.

- Renewable Energy: Wind turbines utilize massive electric generators (which are essentially motors run in reverse) to convert wind energy into electricity. The reliability of these motors is crucial for consistent power generation. Strategic consideration: Investing in robust, durable motors designed to withstand harsh weather conditions is essential for maximizing energy output and minimizing downtime. Improvements in generator efficiency translate directly to increased power output and revenue.

- Robotics: Industrial robots, used in diverse applications such as welding, painting and material handling, rely on precise and powerful electric motors. Each joint of the robot uses a motor for specific movement. Strategic consideration: Focus on the development of compact, high-torque motors optimized for robot arm design, improving flexibility and precision for complex tasks. The use of brushless motors minimizes maintenance needs.

These examples highlight the diverse applications of electric motors and the strategic importance of their performance, reliability, and efficiency across various industries. Continuous innovation in motor technology is critical for improving efficiency, reducing costs, and enabling new possibilities across the board.

1. Strategic Partnerships for Specialized Components: Since 2023, several electric motor companies have focused on forging partnerships with specialized component manufacturers. For example, a motor manufacturer might collaborate with a rare-earth magnet producer to secure a stable supply of high-quality magnets at competitive prices, crucial for high-performance motors. This mitigates supply chain risks and ensures access to cutting-edge materials.

- Investing in High-Efficiency Motor Designs: Organic growth strategies emphasize technological advancements. Companies are heavily investing in R&D to develop more efficient electric motors with higher power density and reduced losses. This includes exploring new winding techniques, advanced cooling systems, and the use of novel materials like silicon carbide. A successful example is a company’s launch of a new motor design boasting a 15% efficiency improvement over previous models, leading to extended EV range and reduced charging times.

- Acquisitions to Expand Product Portfolio: Inorganic growth through acquisition has been prominent. A notable instance is a major motor manufacturer acquiring a smaller company specializing in high-torque motors for heavy-duty electric vehicles. This instantly expands their product offerings into a new market segment, accelerating their market penetration.

- Vertical Integration for Cost Reduction: Several companies are pursuing vertical integration strategies. This involves taking control of different stages of the supply chain, such as manufacturing their own motor controllers or windings. By controlling more aspects of production, companies can reduce costs, improve quality control, and streamline the production process. This reduces reliance on external suppliers and enhances overall profitability.

- Focus on Software and Control Systems: Modern electric motors rely heavily on sophisticated control algorithms. Many companies are now integrating advanced software capabilities into their motors, enabling features like predictive maintenance, optimized energy management, and seamless integration with vehicle systems. This provides a competitive advantage by offering more intelligent and adaptable motor solutions. This software often utilizes AI-driven diagnostics to enhance reliability and reduce downtime.

- Expansion into Niche Markets: Companies are targeting specific market segments beyond the automotive industry. For example, a motor manufacturer might specialize in developing high-precision motors for robotics or industrial automation applications. This diversification reduces reliance on the automotive market’s cyclical nature and opens avenues for sustained growth.

- Sustainability Initiatives: Environmental concerns are driving companies to adopt sustainable manufacturing practices and use eco-friendly materials. This involves reducing carbon emissions throughout the production process, utilizing recycled materials, and promoting circular economy principles within the supply chain. This resonates strongly with environmentally conscious consumers and investors.

Outlook & Summary: The Electric Motor’s Next Chapter

The electric motor is no longer a niche component; it’s the beating heart of the automotive revolution. This article explored the transformative impact electric motors are having on automotive manufacturing, moving beyond simply replacing internal combustion engines to fundamentally reshaping design, production, and supply chains.

Over the next 5-10 years, we can expect several key developments:

- Increased Efficiency and Power Density: Expect to see significant advancements in motor design leading to smaller, lighter, and more efficient motors, maximizing range and performance in EVs. This will involve continued innovation in materials science (e.g., rare-earth magnets) and advanced control algorithms.

- Modularization and Standardization: To streamline manufacturing and reduce costs, we’ll see a move towards modular motor designs and standardized components. This allows for greater flexibility in vehicle platforms and easier scalability of production.

- Integration with Smart Technologies: Electric motors will become increasingly integrated with vehicle control systems, enabling sophisticated features like predictive maintenance, regenerative braking optimization, and improved thermal management. This will require close collaboration between motor manufacturers, software developers, and vehicle integrators.

- Sustainable Supply Chains: Growing concerns about ethical sourcing and environmental impact will drive the development of more sustainable supply chains for electric motor components, focusing on reducing reliance on rare-earth minerals and promoting responsible mining practices.

Key Takeaway: The electric motor’s success is inextricably linked to the overall success of the EV industry. As EV adoption accelerates, the demand for advanced, efficient, and cost-effective electric motors will only intensify. This creates both immense opportunities and significant challenges for manufacturers, demanding innovation, collaboration, and a long-term strategic vision.

The electric motor isn’t just a part of the EV; it is the future of automotive manufacturing. Therefore, how can your organization best position itself to capitalize on these upcoming trends and navigate the challenges that lie ahead?