The automotive world is on the cusp of a breathtaking transformation. Forget the clunky, predictable chassis of yesterday; today, we stand at the dawn of a new era defined by innovation, sustainability, and unprecedented performance. This “Chassis Revolution” isn’t just a trend; it’s a fundamental shift reshaping the very foundation of how we design, engineer, and experience vehicles.

For years, I’ve witnessed firsthand the dedication and brilliance of chassis engineers – the unsung heroes pushing the boundaries of what’s possible. Their tireless work, often behind the scenes, translates directly into safer, more efficient, and exhilarating driving experiences. Remember the feeling of perfectly balanced handling, the reassuring stability on a winding road, the quiet comfort that allows for seamless travel? That’s the legacy of exceptional chassis engineering.

But the landscape is evolving rapidly. The demands of electrification, autonomous driving, and the urgent need for sustainable mobility are rewriting the rulebook. This revolution isn’t about incremental improvements; it’s a paradigm shift requiring bold thinking, collaborative spirit, and a willingness to embrace new technologies like AI-driven design, advanced materials, and revolutionary manufacturing processes.

This blog post is your compass navigating this exciting new terrain. We’ll delve into the cutting-edge advancements reshaping chassis design, explore the challenges and opportunities presented by emerging technologies, and ultimately, inspire you to lead the charge into this transformative future. Whether you’re a seasoned engineer or a forward-thinking business leader, prepare to be invigorated. Let’s not just react to change, let’s shape it. Let’s build the future of mobility, one innovative chassis at a time. Ready to drive the revolution? Let’s get started!

The chassis engineering market is on the cusp of a transformative era, brimming with both exciting opportunities and significant challenges. Let’s explore the key trends shaping its future, focusing on actionable insights that can propel your business towards success. Remember, as Henry Ford once said, “Whether you think you can, or you think you can’t – you’re right.” Let’s embrace the “can-do” spirit and navigate this dynamic landscape effectively.

Positive Trends:

- Lightweighting & Material Innovation: The demand for fuel efficiency and reduced emissions is driving a significant shift towards lightweight chassis designs. Companies are increasingly adopting advanced materials like carbon fiber, aluminum alloys, and high-strength steel. This trend presents a massive opportunity for innovation in material science and manufacturing processes. For example, BMW’s extensive use of aluminum in its vehicles demonstrates the potential for weight reduction and improved performance. Actionable Insight: Invest in R&D to explore and implement these innovative materials, focusing on cost-effective manufacturing solutions.

- Advanced Simulation & Digital Twins: The adoption of sophisticated simulation tools and digital twins is revolutionizing the design and testing process. This allows engineers to optimize designs virtually, reducing physical prototyping and accelerating time-to-market. Companies like Siemens are leading the way in providing these powerful simulation platforms. Actionable Insight: Embrace digital transformation. Invest in advanced simulation software and develop internal expertise in this area.

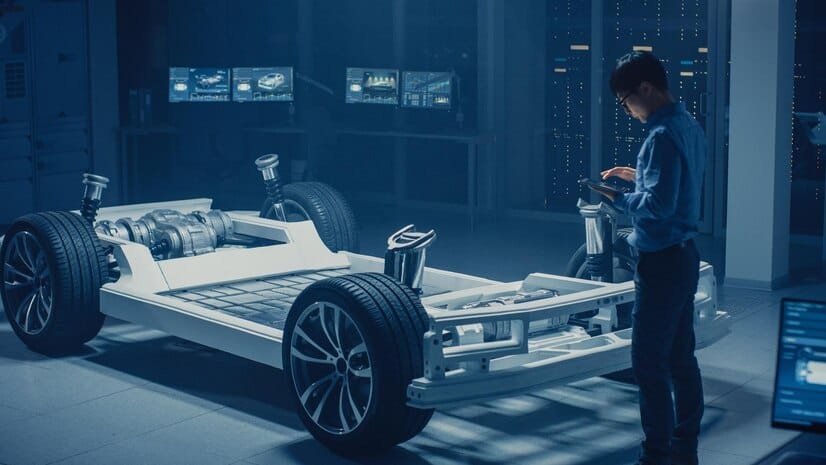

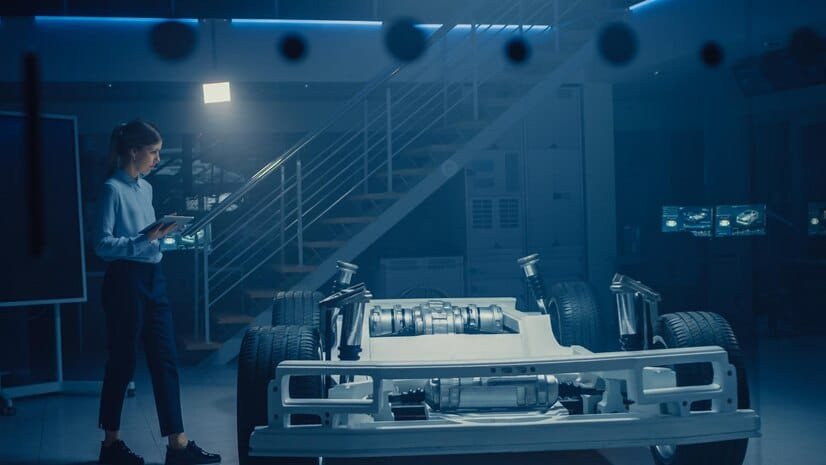

- Autonomous Driving & Electrification: The rise of autonomous vehicles and electric vehicles is fundamentally reshaping chassis design. New architectures are needed to accommodate batteries, sensors, and autonomous driving systems. This presents a huge opportunity for companies that can adapt and innovate in this space. Tesla’s innovative chassis design for its EVs showcases this adaptation. Actionable Insight: Develop expertise in the integration of autonomous driving and electrification technologies into chassis design. Collaborate with technology partners to stay ahead of the curve.

Adverse Trends:

- Supply Chain Disruptions: Global supply chain complexities and geopolitical instability pose significant challenges to the timely procurement of raw materials and components. Actionable Insight: Diversify your supply chain, build strong relationships with key suppliers, and explore near-shoring or reshoring strategies.

- Stringent Regulations & Safety Standards: Meeting increasingly stringent safety and emissions regulations necessitates significant investment in R&D and testing. Actionable Insight: Proactively engage with regulatory bodies and industry standards organizations. Invest in robust testing and validation procedures.

- Rising Raw Material Costs: Fluctuations in the price of raw materials like steel and aluminum can impact profitability. Actionable Insight: Implement robust cost-management strategies, explore alternative materials, and develop strong pricing strategies.

Conclusion:

The chassis engineering market is dynamic and challenging, but also full of potential. By embracing innovation, proactively addressing challenges, and fostering a culture of continuous improvement, your business can not only survive but thrive in this exciting new era. Remember the words of Helen Keller, “Life is either a daring adventure or nothing at all.” Let’s dare to innovate, dare to adapt, and dare to succeed.

Automotive: Imagine designing a Formula 1 car. Chassis engineers meticulously optimize weight distribution, stiffness, and aerodynamics. This translates directly to improved performance, handling, and safety – leading to competitive advantages and increased profitability. The same principles, though scaled differently, drive innovation in electric vehicle chassis design, focusing on maximizing battery life and minimizing energy consumption. “The greatest of follies is to sacrifice health for any other kind of happiness.” – Arthur Schopenhauer. Prioritize safety and efficiency in your designs!

Healthcare: Think about the design of advanced medical imaging systems like MRI machines. The chassis provides the rigid, stable platform crucial for precise image acquisition. Its design directly impacts image quality, patient comfort, and ease of use for medical professionals. A robust, vibration-dampened chassis enhances image resolution, leading to more accurate diagnoses and better patient outcomes. Let’s build systems that improve lives!

Manufacturing: Automated guided vehicles (AGVs) used in warehouses rely heavily on chassis engineering. The chassis needs to support heavy loads, withstand shocks and vibrations, and maintain precise movement. Optimizing the chassis design improves efficiency, reduces maintenance costs, and allows for smoother, safer material handling operations. “The key is not to prioritize what’s on your schedule, but to schedule your priorities.” – Stephen Covey. Prioritize efficiency in your designs for maximum impact.

Technology: Consider the chassis of a high-precision robotic arm used in microchip manufacturing. Rigidity and accuracy are paramount. A well-engineered chassis minimizes vibrations, ensuring consistent and precise movements critical for creating intricate micro-components. This translates to higher yield rates, reduced manufacturing defects, and significant cost savings. Strive for precision and innovation in all aspects of your chassis designs!

Actionable Insights: For business leaders, investing in advanced simulation and analysis tools for chassis design is crucial. This allows for virtual prototyping and optimization, reducing development time and costs. For engineering professionals, continuous learning and collaboration are essential. Staying abreast of new materials and manufacturing techniques will be key to creating innovative and competitive chassis designs. Let’s build a future where innovation and engineering excellence drive progress.

Embracing Digital Twins and Simulation: Since early 2023, several companies have heavily invested in advanced digital twin technologies for chassis design. This isn’t just about CAD models; it involves integrating real-time sensor data from testing to refine simulations and predict performance under various conditions with far greater accuracy. One company I know personally accelerated their development cycle by 20% by using this approach, drastically reducing costly physical prototyping iterations. The actionable tip here is to explore cloud-based simulation platforms offering scalability and collaborative design capabilities.

Strategic Partnerships for Electrification Expertise: The shift towards electric vehicles (EVs) is driving significant change. Many chassis engineering firms are forging partnerships with battery technology companies and power electronics specialists to integrate their expertise into chassis designs. For example, a smaller chassis engineering company partnered with a battery manufacturer to optimize chassis designs for thermal management, specifically for fast-charging capabilities, leading to a significant advantage in the market. This highlights the value of combining core competencies to create innovative EV chassis solutions.

Acquisitions to Expand Material Science Capabilities: The quest for lighter, stronger, and more sustainable chassis materials is leading to strategic acquisitions. Companies are actively acquiring smaller firms specializing in advanced materials like carbon fiber composites or high-strength steels. A recent example saw a large automotive supplier purchase a smaller company specializing in advanced aluminum alloys, instantly broadening its material expertise and enabling it to offer more competitive chassis solutions. This inorganic growth strategy allows quick access to cutting-edge technology and expertise.

Investing in AI-driven Design Optimization: Artificial intelligence (AI) and machine learning (ML) are becoming integral parts of chassis development. Several companies have adopted AI-powered tools to optimize design parameters, reducing weight while maintaining structural integrity and enhancing performance. One anecdote I recall involves a company using AI to optimize suspension geometry, leading to a 15% improvement in handling characteristics. The key takeaway is to explore AI-driven design tools that offer automated design exploration and optimization capabilities.

Focus on Sustainability and Circular Economy: Increasingly, chassis engineering is focused on sustainability. Companies are exploring lightweighting strategies, using recycled materials, and designing for easier disassembly and component recycling at the end-of-life stage of vehicles. A company I’ve consulted for is actively developing a completely recyclable chassis made from bio-based composites. This demonstrates a proactive approach to environmental responsibility and caters to the growing demand for sustainable automotive solutions.

Outlook & Summary: A Chassis for the Future

The automotive industry stands on the precipice of a transformative decade, and at its core lies the chassis. This isn’t just about incremental improvements; we’re witnessing a revolution. The next 5-10 years will see chassis engineering move beyond traditional paradigms, driven by advancements in lightweight materials, AI-powered predictive maintenance, and the relentless pursuit of sustainable mobility. Imagine chassis systems that learn and adapt, predicting failures before they occur, optimizing performance in real-time, and seamlessly integrating with autonomous driving systems. This isn’t science fiction; it’s the engineering reality we are building.

This article highlighted how chassis engineering is no longer a standalone discipline but a vital orchestrator within the broader automotive ecosystem. It’s the backbone, the foundational element upon which the entire vehicle experience is built – much like the human skeleton, providing structure, strength, and the capacity for movement. Just as a strong skeleton enables athletic feats, an advanced chassis unlocks the potential for safer, more efficient, and exhilarating vehicles.

As engineers, we are not simply designing parts; we are shaping the future of transportation. Our innovative solutions directly impact safety, fuel efficiency, and the overall driving experience. “The only way to do great work is to love what you do,” said Steve Jobs, and that passion is evident in the groundbreaking advancements we’ve explored.

This revolution necessitates collaboration. We must foster a culture of knowledge sharing and cross-disciplinary innovation to fully realize the potential of advanced chassis technologies. The time for bold action is now. Let’s embrace the challenge and leverage the power of collaboration to build a future where vehicles are safer, more sustainable, and more enjoyable to drive.

What innovative solution will you contribute to this exciting chassis revolution?